VCON rebar, manufactured by means of our proprietary production system,

which has a high level of quality control, is a product with a high performance

history and superb quality, among its other excellent features. The product

meets many strict regulations and standards and is ideally suited to a

wide range of applications.

|

|

|

Choose between three product categories according to the nature of the

construction work or its various purposes.

|

|

|

|

|

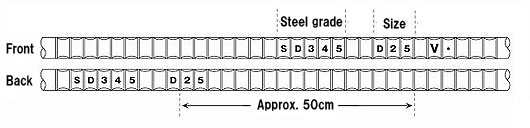

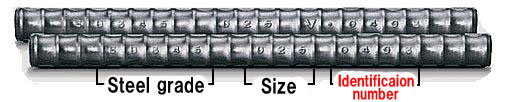

OTANI marks each of our rebars with both its steel grade and size. This

makes it possible to visually check the steel grade and size, making them

much easier to work with and bringing greater accuracy to the construction

site.

<Steel grade and size markings>

By setting more control items than JIS, instigating stringent controls

of chemical constituents and seeking the best shape for the ridges, we

have created products with a high degree of weldability and workability.

We also carry out a variety of tests and inspections in addition to inspection

items that are covered by JIS standards.

* We started manufacturing STANDARD VCON marked with steel grade and size

on February 1 2010. You may find the old-style products mixed in with the

new “steel grade and size” marked ones arriving in your orders for a while.

They can both be used as STANDARD VCON. There is no difference in quality

between them. We apologize for any inconvenience or confusion this might

cause, and hope that you will understand and appreciate our position.

|

|

|

|

|

|

|

| Type code |

Chemical constituents % |

| C |

Si |

Mn |

P |

S |

C+Mn/6 |

| SD295A |

- |

- |

- |

0.050 or less |

0.050 or less |

- |

| SD345 |

0.27 or less |

0.55 or less |

1.60 or less |

0.040 or less |

0.040 or less |

0.50 or less |

| SD390 |

0.29 or less |

0.55 or less |

1.80 or less |

0.040 or less |

0.040 or less |

0.55 or less |

| SD490 |

0.32 or less |

0.55 or less |

1.80 or less |

0.040 or less |

0.040 or less |

0.60 or less |

|

|

|

|

| Type code |

Yield point or

proof stress

N/mm2 |

Tensile strength

N/mm2 |

Tensile strength test specimen |

Elongation(※)

% |

Bendability |

| Bending angle |

Inner radius |

| SD295A |

295 or higher |

440-600 |

Equivalent to a No.2 test piece |

16 or higher |

180° |

D16 or lower

1.5 times greater than the nominal diameter |

| Equivalent to a No.14A test piece |

17 or higher |

Higher than D16

2 times greater than the nominal diameter |

| SD345 |

345-440 |

490 or higher |

Equivalent to a No.2 test piece |

18 or higher |

180° |

D16 or lower

1.5 times greater than the nominal diameter |

| Equivalent to a No.14A test piece |

19 or higher |

Higher than D16 and equal to or lower than D38

2 times greater than the nominal diameter |

| SD390 |

390-510 |

560 or higher |

Equivalent to a No.2 test piece |

16 or higher |

180° |

2.5 times greater than the nominal diameter |

| Equivalent to a No.14A test piece |

17 or higher |

| SD490 |

490-625 |

620 or higher |

Equivalent to a No.2 test piece |

12 or higher |

90° |

D25 or lower

2.5 times greater than the nominal diameter |

| Equivalent to a No.14A test piece |

13 or higher |

Higher than D25

3 times greater than the nominal diameter |

|

|

|

| ※If the bar is designated as larger than D32: for every of 3 point increase

in the bar designation, 2% should be subtracted from the elongation value

listed; however, the total subtracted amount should not exceed 4%. |

|

|

| Bar designation |

Nominal diameter

(d)mm |

Nominal perimeter

( I)cm |

Nominal cross sectional area

(S)cm2 |

Unit mass

kg/m |

Maximum average spacing of ridges

mm |

Ridge height |

Maximum value of the sum of spaces between ridges

mm |

Minimum

mm |

Maximum

mm |

| D10 |

9.53 |

3.0 |

0.7133 |

0.560 |

6.7 |

0.4 |

0.8 |

7.5 |

| D13 |

12.7 |

4.0 |

1.267 |

0.995 |

8.9 |

0.5 |

1.0 |

10.0 |

| D16 |

15.9 |

5.0 |

1.986 |

1.56 |

11.1 |

0.7 |

1.4 |

12.5 |

| D19 |

19.1 |

6.0 |

2.865 |

2.25 |

13.4 |

1.0 |

2.0 |

15.0 |

| D22 |

22.2 |

7.0 |

3.871 |

3.04 |

15.5 |

1.1 |

2.2 |

17.5 |

| D25 |

25.4 |

8.0 |

5.067 |

3.98 |

17.8 |

1.3 |

2.6 |

20.0 |

| D29 |

28.6 |

9.0 |

6.424 |

5.04 |

20.0 |

1.4 |

2.8 |

22.5 |

| D32 |

31.8 |

10.0 |

7.942 |

6.23 |

22.3 |

1.6 |

3.2 |

25.0 |

| D35 |

34.9 |

11.0 |

9.566 |

7.51 |

24.4 |

1.7 |

3.4 |

27.5 |

| D38 |

38.1 |

12.0 |

11.40 |

8.95 |

26.7 |

1.9 |

3.8 |

30.0 |

| D41 |

41.3 |

13.0 |

13.40 |

10.5 |

28.9 |

2.1 |

4.2 |

32.5 |

| D51 |

50.8 |

16.0 |

20.27 |

15.9 |

35.6 |

2.5 |

5.0 |

40.0 |

|

|

|

|

|

|

|

|

| Size |

Tolerance per piece |

|

Tolerance per set |

| From D10 to D16 |

±6% |

|

±5% |

| From D16 to D29 |

±5% |

|

±4% |

| Higher than D29 |

±4% |

|

±3.5% |

|

|

|

| Length |

Tolerance |

| 7 m or less |

+40mm

0 |

| Longer than 7 m |

For every 1 m increase in length (or fraction of 1 m), 5 mm should be added

to the upper tolerance value; however, the value should not exceed 120

mm. |

|

|

|

|

|

|

|

|

|

|

|

The SUPER VCON is our original product that displays a 4-figure identification

number (*) after its steel grade and size, making it suitable for construction

work requiring strict material control and high reliability. This ensures

that each rebar used on the site is traceable, even after the product bundles

have been unbound or the rebars have been cut, thus making thorough quality

control possible. (patented)

* The identification number on SUPER VCON is a proprietary number used

by OTANI Steel corresponding to the molten steel lot number. |

|

|

|

|

| It is not only our standard products that achieve VCON performance. We

also manufacture custom-made products to meet such customer requirements

as specific chemical constituents or dimensions, as well as the need to

take into account the customer’s machining and use conditions. Please feel

free to consult with us about the length, mechanical properties and chemical

composition you are looking for. |

|

|

|

|

|